The Impact of Thermal Management Materials on Next-Generation Electronics Performance

As electronic systems continue to evolve toward higher power density, smaller form factors, and faster processing speeds, thermal management has become one of the most critical constraints in system design. From high-performance computing and AI accelerators to power electronics and edge devices, excess heat now directly limits reliability, efficiency, and usable lifespan.

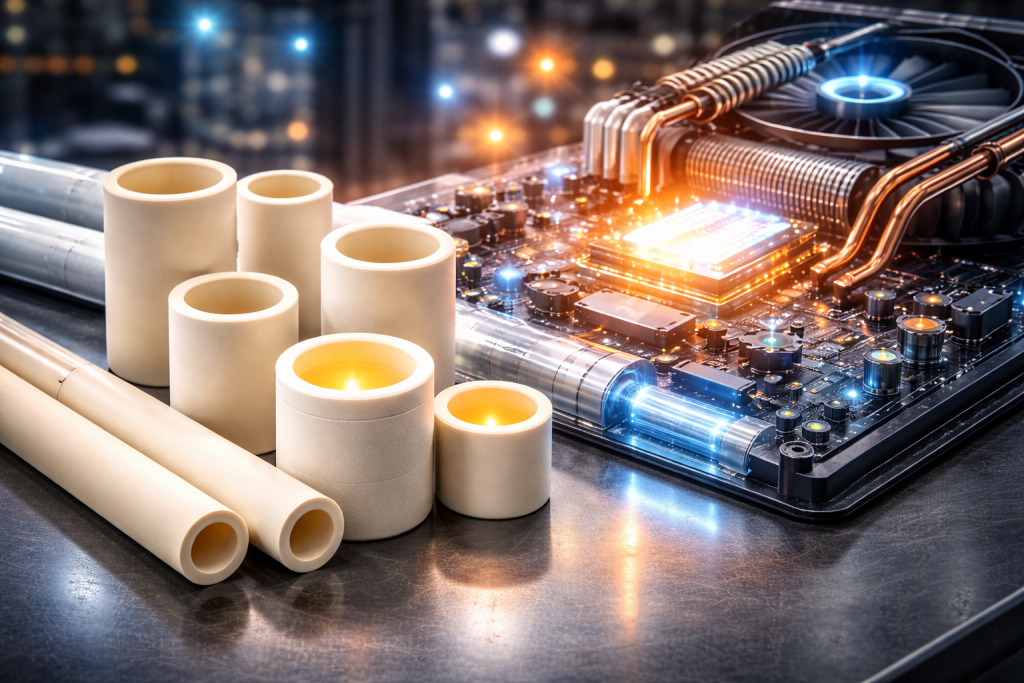

While advances in chip architecture and cooling technologies have improved performance, they have also exposed weaknesses in the materials surrounding heat-generating components. In many next-generation electronic systems, maintaining stable thermal pathways depends on structural elements such as alumina ceramic tubes used to enhance thermal management efficiency in next-generation electronic systems, which help preserve dimensional integrity and insulation performance under continuous thermal load.

As electronics push closer to their physical limits, thermal management is no longer an auxiliary design consideration—it is a system-level performance driver.

Why Thermal Stability Matters More Than Ever

Modern electronics operate under conditions that were once considered extreme. High switching frequencies, increased current densities, and compact layouts concentrate heat in localized regions. Even minor thermal fluctuations can lead to signal drift, material fatigue, or accelerated aging of sensitive components.

Traditional materials used in structural or insulating roles often struggle to maintain consistent behavior under prolonged heat exposure. Thermal expansion, softening, or chemical interaction with surrounding components can compromise alignment and heat flow paths. Over time, these effects reduce cooling efficiency and increase the risk of unexpected failure.

Thermal stability at the material level is therefore essential to sustaining predictable electronic performance.

Material Selection in Advanced Thermal Management Architectures

Effective thermal management requires more than active cooling solutions such as fans or liquid loops. Passive materials that guide, isolate, or contain heat play a decisive role in how efficiently systems dissipate energy.

Advanced ceramics, particularly alumina-based materials, are increasingly evaluated for these roles due to their low thermal expansion, electrical insulation, and resistance to thermal degradation. In applications where components must remain dimensionally stable despite repeated heating cycles, these properties help preserve mechanical and thermal interfaces.

By maintaining consistent geometry, such materials support the effectiveness of downstream cooling strategies rather than working against them.

Supporting Electronics Development Through High-Temperature Testing

Before next-generation electronic systems reach production, materials and components undergo extensive validation under simulated operating conditions. High-temperature testing is used to evaluate thermal endurance, chemical compatibility, and long-term stability.

In this development phase, alumina ceramic crucibles applied in high-temperature material testing for advanced electronics development are commonly used to provide controlled, inert environments for evaluating candidate materials. Their ability to withstand extreme temperatures without reacting or deforming ensures that test results reflect true material behavior rather than container-induced artifacts.

Accurate testing at this stage helps engineers identify thermal risks early, reducing costly redesigns later in the product lifecycle.

Thermal Management as a Reliability Strategy

Thermal issues rarely cause immediate failure. Instead, they manifest gradually through reduced performance, increased error rates, or shortened component lifespan. This makes thermal management a long-term reliability strategy rather than a short-term optimization.

Materials that maintain stable thermal and mechanical properties reduce the accumulation of micro-stresses that lead to premature degradation. Over extended operating cycles, this stability translates into fewer maintenance interventions, more predictable performance, and improved system availability.

For electronics deployed in critical or remote environments, these benefits are particularly significant.

Looking Ahead: Materials as Enablers of Electronic Innovation

As electronics continue to advance, thermal management challenges will intensify rather than diminish. Higher integration levels and emerging applications such as AI inference at the edge or wide-bandgap power electronics will demand materials capable of operating reliably under sustained thermal stress.

The future of electronics performance will therefore depend not only on smarter chips and better cooling designs, but also on the materials that support them. By integrating thermally stable, high-performance materials into system architectures, designers can unlock new levels of reliability and efficiency.

In this context, thermal management materials move from the background into a central role—quietly enabling the next generation of electronic innovation.